NEWS

A new dimension of prefabrication

bauen mit Holz 1.2024

Demographics in Germany have an immense influence on the construction market. Over the last 30 years, the proportion of 25 to 44-year-olds has decreased, while the proportion of older people aged 65 and over has increased. This has consequences for housing concepts, as the group of people wanting to build single-family homes is shrinking; the demand for multi-family homes and commercial construction is growing at the same rate. Bauer Holzbau is focusing on these growth markets and is responding to the changing conditions with modern production methods.

Industrialised timber construction

HOB 10.2023

For the third time, numerous representatives from the timber construction industry met at Reichenbacher Hamuel at the end of October for an expert meeting. The topic was industrial production in timber construction, and around 30 guests attended the event at the company’s headquarters. A further 90 followed the presentations online, which focussed on thinking and manufacturing in modular construction in an industrial context.

Entry into CNC machining with Reichenbacher

HOB 8.2023

The small Nos joinery from the Wetterau district of Hesse has arrived in the modern CNC world: Founded in 1949, the company said goodbye to tedious, old-fashioned manufacturing a year ago. The ideal entry into CNC technology was provided by the Opus machining center from Reichenbacher.

Solving large tasks intuitively

exakt 10.2023

Companies in industry and trade face a major challenge when it comes to automation. Because machines alone are not enough — in order to guarantee consistently high product quality, intelligent software must be used so that employees can control processes, operate machines and carry out programming without errors, even after only a short training period.

Variety is the motto

BM 10.2023

By investing in modern 5‑axis CNC technology, Moralt AG has not only noticeably increased its flexibility and performance. At the same time, the manufacturer of door blanks has opened a new chapter in terms of individuality and data consistency.

Unpacking and depowdering of 3D printed metal parts

Press release

The removal of unfused powder is a central step in the postprocessing of metal parts made using additive manufacturing. For years, systems from Solukon have removed powder automatically from parts manufactured with LPBF processes. A project with Reichenbacher Hamuel GmbH…

Sustainable building with wood

HOB 5+6.2023

Timeless building has been a tradition at Bauer Holzbau for almost 140 years. Craftsmanship is combined with progress and is exemplified in the form of modern production facilities and logistics concepts. Everything comes from a single source, from architecture to construction and specialist planning to the overall completion of a building project. Turnkey single-family houses, developer models and object buildings in residential construction…

Extremely fast and very precise

HK 3.2023

Being a pioneer in a field is one thing, but achieving this in a technically and economically sensible way is another. According to Klaus Feile, CEO of Moralt AG, the acquisition of a new 5‑axis CNC system was a logical investment in the future. His goal: The traditional company should continue to play a leading role as a manufacturer of door pre-products and supplier of system solutions for functional doors for interior and exterior use.

Cheek milling machine farewell!

dds 3.2023

Stefan Nos and son Benedikt laboriously made stairs with exotic machines. Now they have drawn a line and banned from the workshop not only the cheek milling machine for milling steps and the staircase boring machine.

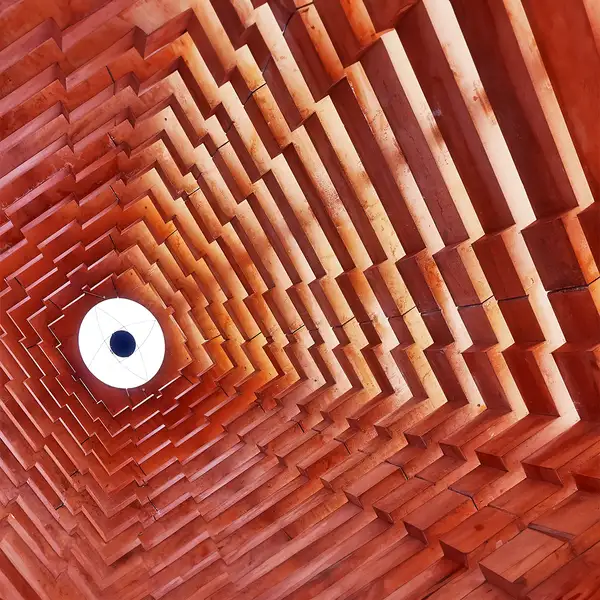

The crazier the better

HK 6.2022

The 3D formwork bodies that give the concrete its shape are planned, prefabricated and assembled with computer assistance. The more geometrically complex the formwork is, the more flowable and at the same time pressure-resistant the concretes used have to be.