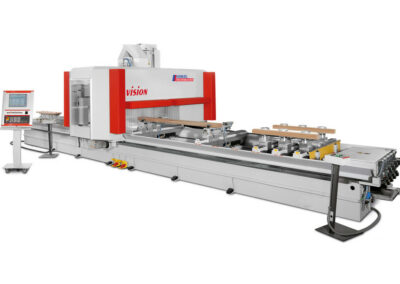

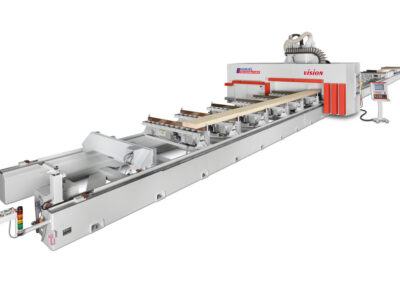

VISION-U-/L

The components show what the machine can do

Equipped with a cardanic working head, the basic VISION is transformed into the VISION Sprint to provide small and medium-sized joinery and interior design companies with low cost access into 3‑dimensional machining. The VISION Sprint unlocks the unique potential that high-speed 5‑axis machining offers.

The positioning accuracy of the working aggregate means that the VISION Sprint is excellently suited to the requirements of stair and door production. The two swivelling axes are inclined at 45° to one another and, with optimum tool length, their centre axes intersect at the working point of the tool. By this principle the position of the working point does not change when swivelling in space, which means that no compensation movement in the linear axes is necessary. Thus the working area of the machine is only slightly reduced by the employed tool length when in the horizontal position.

The proven VISION machining centre already has an impressive track record of success in many demanding applications around the world. And, like all Reichenbacher Hamuel machines, the VISION features outstanding machine rigidity – the basis for precision machining. To meet the market challenges of today, and tomorrow, we have developed two new VISION models; the VISION‑U and VISION‑L.

A major feature of these machines is that they can be supplied with a choice of table dimensions and a wide variety of different heads. These features can be combined for single and parallel machining with up to two independent Y‑slides. It is possible to use different working heads next to each other or one behind the other, thanks to the extremely rigid machine construction. For example, two big 5‑axis heads with comprehensive additional equipment would cover many different application fields.

Configuration examples

VISION-U-/L

- Even after 20 years we are still market leader with our safety concept for machines with mobile portals

- Enclosed portal made of sheet steel with safety bumpers

- No safety shut-off mats

- No safety barriers

- Safe view of the working process through generously dimensioned windows