House / Objectconstruction

Modern house and commercial construction combines a healthy indoor climate with stylish architecture and high functional standards. Sustainable buildings impress above all with their low energy consumption and high degree of prefabrication.

Bauer Holzbau building envelopes & facade elements

Timeless building has a tradition at Bauer Holzbau. They combine craftsmanship with modern production facilities and logistics concepts. Thus, they realise turnkey single-family homes and object buildings using sustainable building materials.

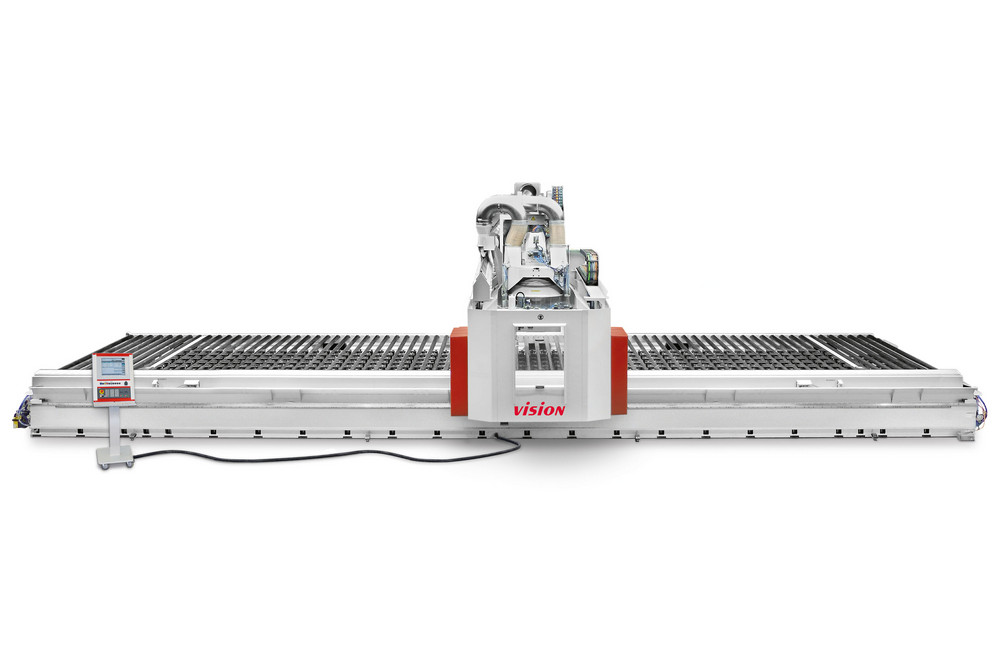

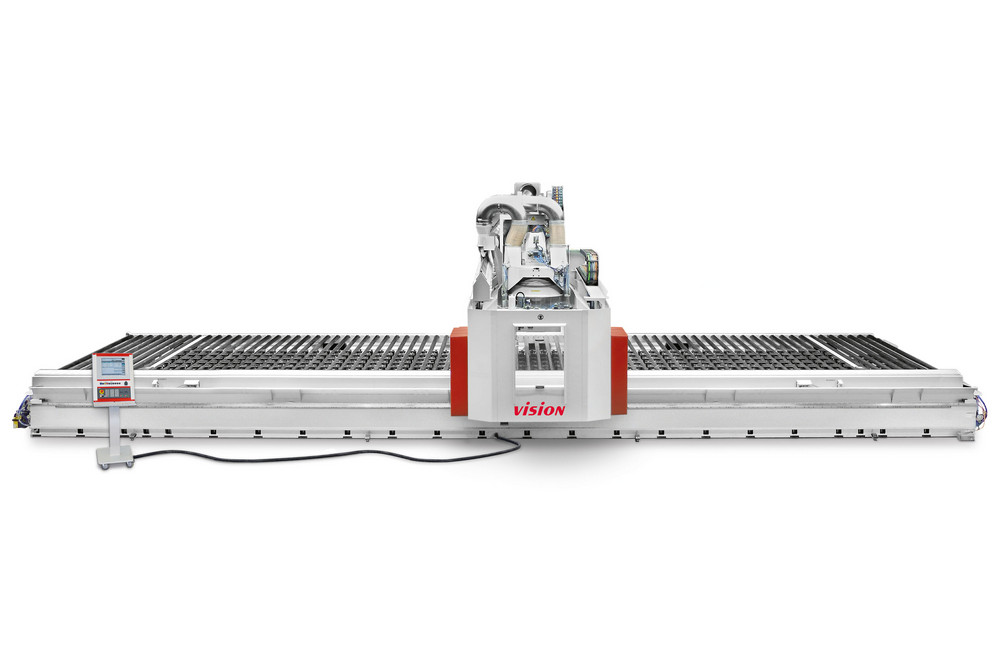

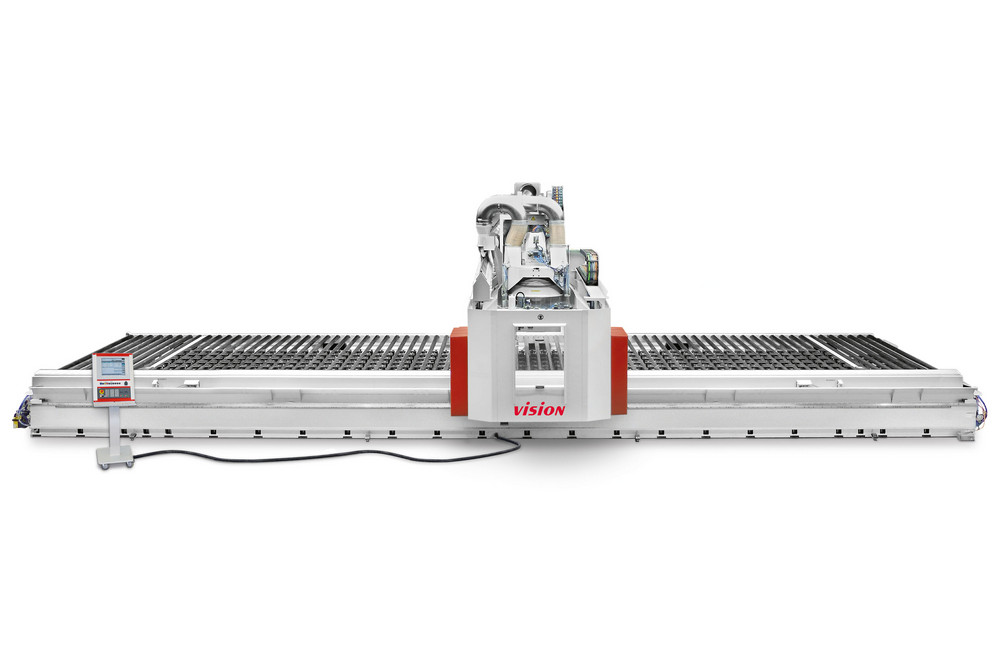

The modern CNC system VISION-III-TTT‑H 5‑axis with grooved HPL table plate is in use in the economic prefabrication of building components. At a length of 9 m, a width of 3.6 m and a Z‑stroke of 780 mm, this system is ideally suited for timber construction.

Holzbau Reichel planning and construction of bridges

Holzbau Reichel represents the entire range of classic timber construction. The company specialises mainly in the building of roof trusses and formwork for bridge construction.

They invested in an OPUS-5R to intensify in-house production depth. It allows the processing of panels with dimensions of 2.5 m x 1.25 m with little effort: recesses, notches, cavities and the necessary connecting elements for very complex component geometries can be realised within short.

Regnauer Fertigbau house walls and ceilings

Regnauer Fertigbau are producing house walls and ceilings with a high degree of prefabrication. They masterly combine a healthy indoor climate, stylish architecture and high functional and aesthetic standards.

The highly efficient ECO-3313‑A through-feed system has been integrated into an existing production line and has become a central component in the overall process. An area storage system precedes it, where the arrangement of the panel stacks is in line with the quantities required.

Glass Bauunternehmung all areas of construction

The complexity of geometrically demanding structures in combination with fair-faced concrete is a remarkable challenge, as formwork construction requires enormous expertise. Glass Bauunternehmung specialises in the production of complex formwork bodies from solid wood and chipboard.

The VISION-III-TT 5‑axis machining centre with grooved HPL table surface aims at process optimisation and reaches entirely new dimensions where accuracy, speed and flexibility are concerned.

Derix Glued Laminated Timber

The Derix group of companies has specialised in glued laminated timber for construction purposes. Their priority is on hall structures, which includes also highly complex shapes.

Today they are working with three identical lines of type VISION-III-TT-5-axes, each of which is equipped with a beam table 16,500 x 3,600 mm that consists of 23 steel traverses with wooden beam tops, as well as with a conveyor.

innbau-beton High-Quality Precast Concrete Elements

Die Schalung ist eine Form, in die Frischbeton zur Herstellung von Betonbauteilen eingebracht wird und die nach dem Erhärten entfernt wird. Vor den Toren Münchens ist die Firma innbau-beton zuhause, die Bauunternehmer mit hochwertigen Betonfertigteilen beliefert.

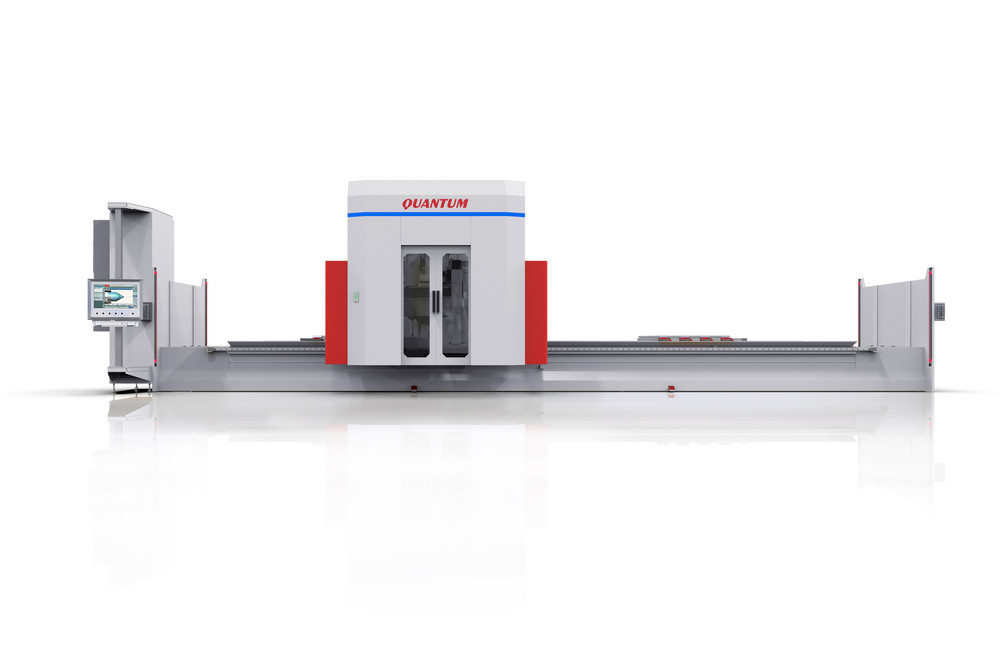

Seit zwei Jahren werden diese Schalungsplatten in Größen bis zu 6.000 x 2.000 mm automatisiert auf der QUANTUM gefertigt. Durch den Einsatz der Maschine erreicht innbau-beton im Vergleich zu früher eine Zeitersparnis von rund 25 Prozent.

Balteschwiler Wall and Ceiling Panels / Outer Facades

The manufacture of wall and ceiling panels, as well as of outer facades, requires big, reliable machining systems.

Using the VISION-III-TTT, the cutting and machining centre for large formats, Balteschwiler perform the fully automatic cutting, milling, drilling, chamfering and grinding of complex panel and structural components of up to 13.5 m in length, 3.5 m in width and 250 mm thickness!

Renggli Sustainable Buildings

Apart from their high level of comfort, sustainable timber buildings impress mainly by their low energy requirements.

As the degree of prefabrication for modular timber construction systems is an ever-increasing one, Renggli rely on modern production lines, which comprise also the panel machining centre ECO-3533‑B Nesting.