AMS 400

Selective laser melting

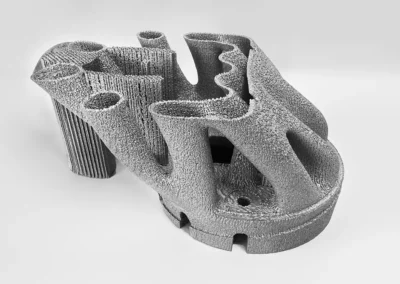

The AMS 400 produces components using the L‑PBF (laser-powder bed fusion) process. The integrated powder preparation and inert gas system (nitrogen N2) also place great emphasis on sustainability and safety.

The handling of the components takes place outside the building area, and their transfer between the individual operations is semi-automatic. It is an open system where the equipment can be configured for various CAD/CAM interfaces and process controls. Thus, the customer decides how best to integrate the system into the existing engineering and production environment.

AMS 400

The customizable AMS series is flexible in terms of customer requirements regarding building area size, wave length or post processes. This new type of 3D printing system combines all manufacturing processes in one fully automated process flow.

Compact end-to-end solution

For more information, read the technical article on “Unpacking and fine cleaning of 3D printed metal parts” for free!

Industry brochure

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.