Specialist in

CNC milling machines

CNC-technology at its best

We have made a name for ourselves worldwide as a manufacturer of first-class CNC milling machines. At the site in Dörfles-Esbach near Coburg, 5‑axis machining centers are developed and manufactured that have the highest safety standards and are used in aircraft, automotive, ship and rail vehicle construction as well as in the woodworking industry or by manufacturers of components made of aluminum, plastic or composite materials. In the field of additive manufacturing, we are breaking completely new ground with customer-oriented solutions in industrial applications.

Reichenbacher Hamuel GmbH currently employs more than 220 people and is a subsidiary of the group of companies of the SCHERDELGroup, a major automotive supplier that currently employs around 6,300 people.

Our Newsletter

Stay up to date!

Informed at a glance:

- Latest news from the Reichenbacher-Hamuel group of companies

- News from industry and the crafts

- Insider tips for machining aluminium, composites, wood and new materials or application of future-oriented technologies

- Advance notice of events and activities

Sign up for our newsletter and never miss any news again.

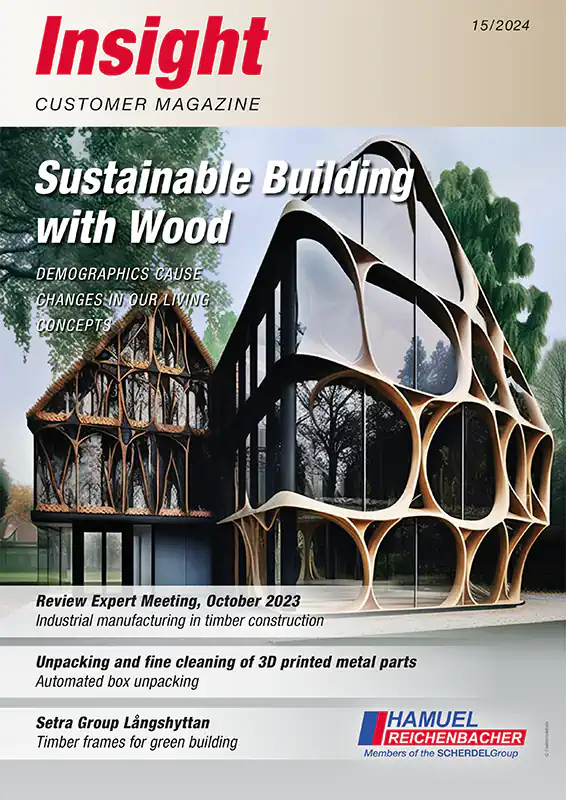

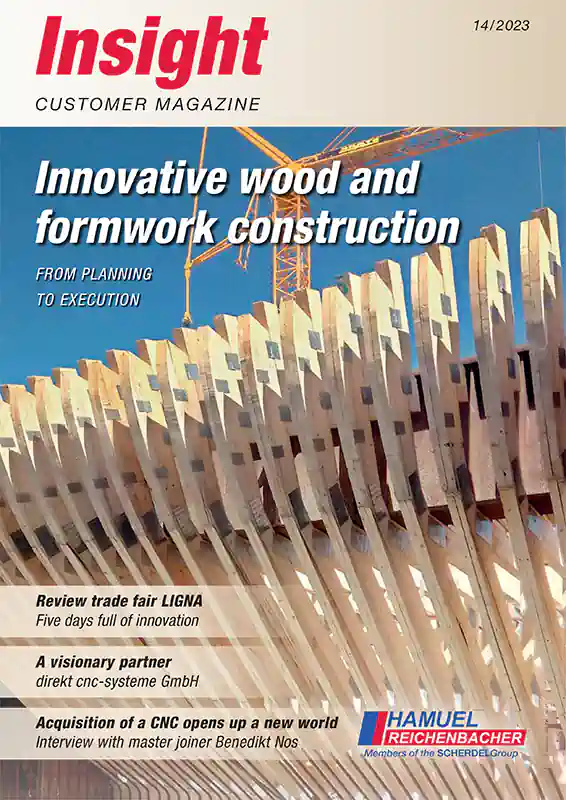

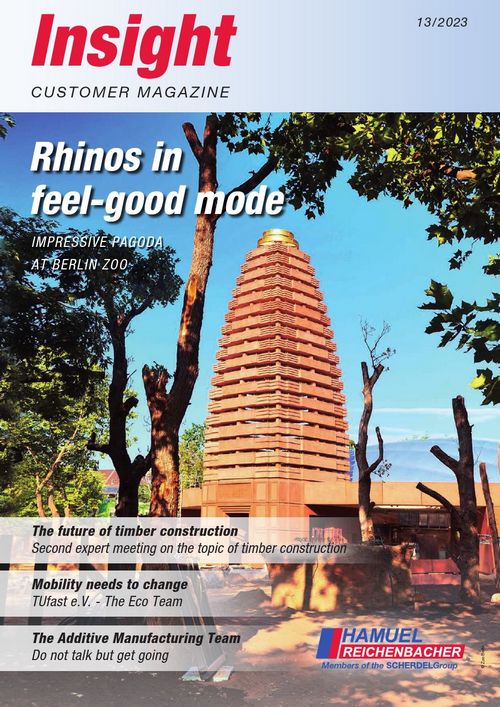

Insight - The customer magazine

Twice a year, we put together the best of news from the group of companies, interesting user reports and interviews with experts on current industry topics or insights into the working world of colleagues.

Latest news

The latest from the trade press

A new dimension of prefabrication

bauen mit Holz 1.2024

Demographics in Germany have an immense influence on the construction market. Over the last 30 years, the proportion of 25 to 44-year-olds has decreased, while the proportion of older people aged 65 and over has increased. This has consequences for housing concepts, as the group of people wanting to build single-family homes is shrinking; the demand for multi-family homes and commercial construction is growing at the same rate. Bauer Holzbau is focusing on these growth markets and is responding to the changing conditions with modern production methods.

Industrialised timber construction

HOB 10.2023

For the third time, numerous representatives from the timber construction industry met at Reichenbacher Hamuel at the end of October for an expert meeting. The topic was industrial production in timber construction, and around 30 guests attended the event at the company’s headquarters. A further 90 followed the presentations online, which focussed on thinking and manufacturing in modular construction in an industrial context.

Entry into CNC machining with Reichenbacher

HOB 8.2023

The small Nos joinery from the Wetterau district of Hesse has arrived in the modern CNC world: Founded in 1949, the company said goodbye to tedious, old-fashioned manufacturing a year ago. The ideal entry into CNC technology was provided by the Opus machining center from Reichenbacher.

Solutions

Industries rely on special solution approaches

Aircraft Construction

Vehicle Construction

Lightweight Construction

Interior Construction

Instrument Construction

House / Objectconstruction

Window / Door Construction