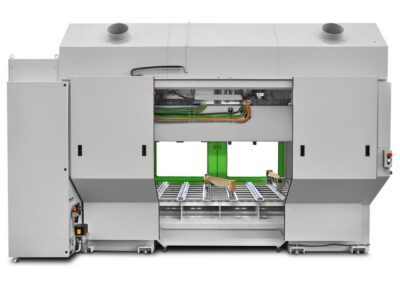

ECO-LT

The machining centre ECO-LT is to expand the proven ECO-NT series of Reichenbacher Hamuel by a version available at a favourable price. It has specifically been developed for the machining of plastics, aluminium and composites (CFRP, GRP) and permits the fully automated milling of cutouts, circumferences and profiles.

The low-vibration portal frame with its fixed machining table on a stable base convinces by utmost machining quality at maximum feed rates. The machine is completely encased in a protective cabin including ceiling element, while allowing also for an optimum chip removal. The two versions available meet most different customer requirements.

The ECO-LT features durable mechanical and electronic components. The technical optimisation of its assemblies warrants for process reliability and operating efficiency.

Configuration examples

ECO-LT

- One cardanic 5‑axes working unit with an undercut of up to 46° that can be equipped with various head versions

- Spindle power 14 kW, 1,000 to 24,000 rpm, HSK F63

- Tool changer with 7 places

- Fixed machining table (steel bars, grooved table with HPL or aluminium plate)