Aircraft Construction

Aerodynamic surfaces and structural components for aircraft must satisfy the highest demands. Machining accuracy is therefore the measure of all things.

F/LIST Cabin Interiors

The focus of exquisite cabin interiors for aircraft and yachts is on first-class surface quality. Their production calls for progressive manufacturing processes.

F/LIST rely on several CNC-lines type VISION-II. They meet the demands for increasing variability as to dimensions and materials.

MECAPLEX AG Transparencies

The manufacture of transparencies for airplanes and helicopters requires enormous specialisation, as they are subject to highest loads when the aircraft is airborne.

MECAPLEX AG machine composites, acrylic glass, polycarbonate, GRP and CFRP on the ECO-2616‑A. The line is equipped with glass scales for heat monitoring to account for the demanding materials to be processed.

MT-Propeller Blades

MT-Propeller produce blades for aircraft, hovercraft and wind tunnels from natural composites. Numerous undefined aerodynamic surfaces present a huge challenge.

According to CAD/CAM specifications, the blades are milled from wooden blocks by high-quality CNC-machines type VISION-Inline; depending on their size either several simultaneously side by side or a single one or pair lengthwise.

Diehl Aviation Manufacturing of Assemblies from Honeycomb Material

Evidence for the innovative capacities of Tier‑1 Diehl Aviation is their manufacturing of assemblies for the aircraft industry from honeycomb material.

The ECO-NTX-1720 Duo produces side walls with window openings, ceilings, storage compartments, cabin interiors, doors and door frames, as well as other three-dimensional components, for most diverse types of aircraft.

Premium AEROTEC Structural Components

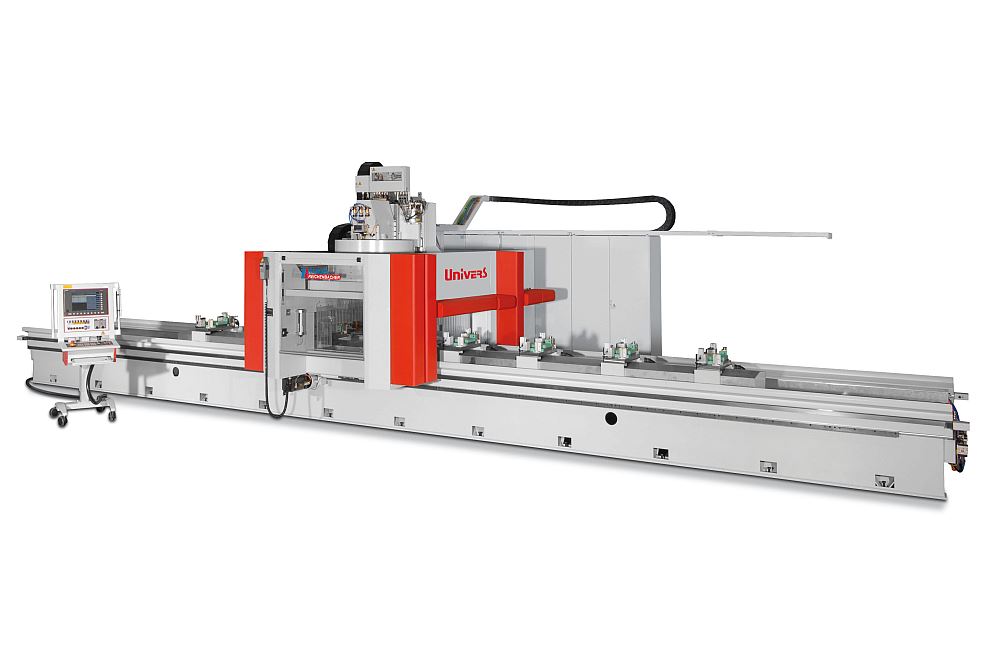

Machining accuracy is the non-plus ultra for structural components in military and civil aircraft.

Premium AEROTEC use heavyduty centres type UNIVERS and VISION-III‑H for the machining of floor crossbars and seat rails from CFRP and of the aluminium honeycomb structure for wing components.