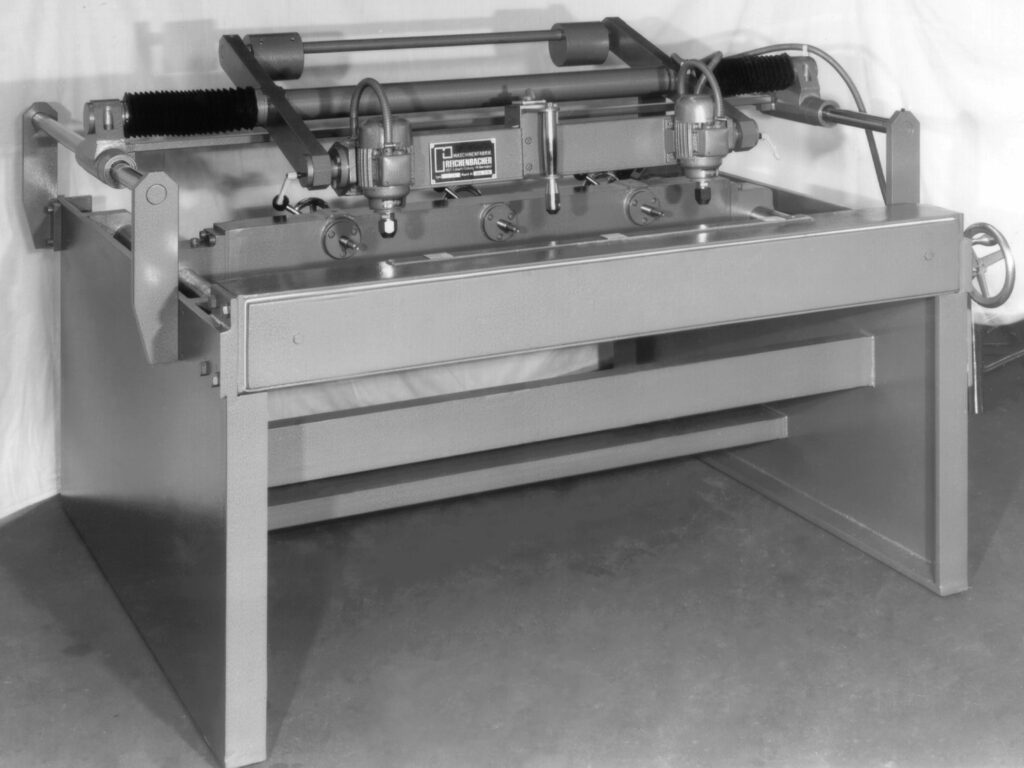

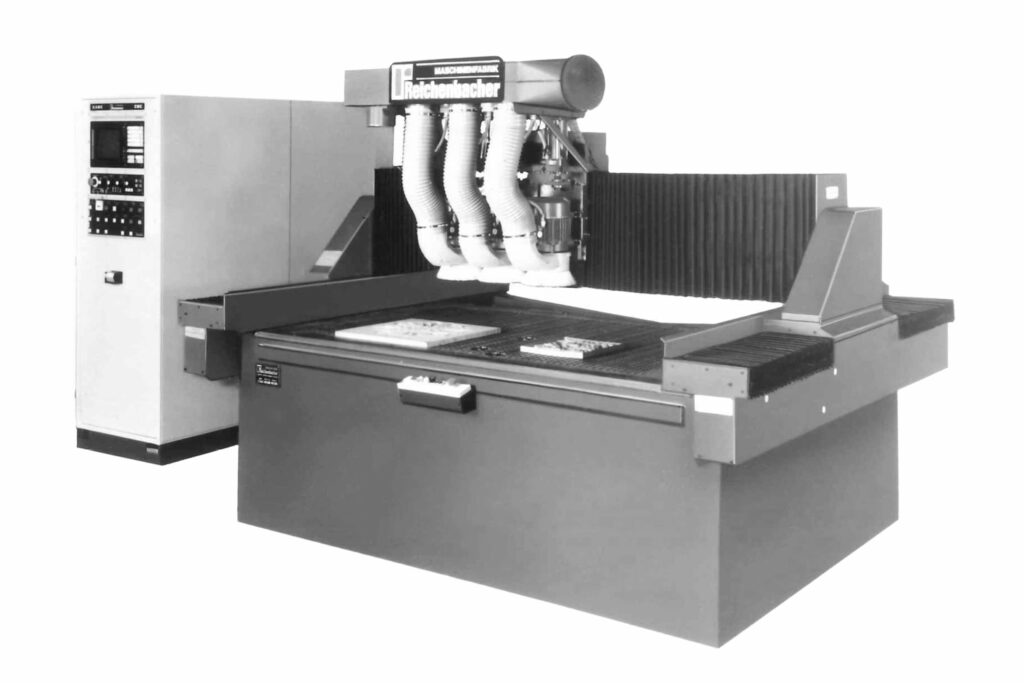

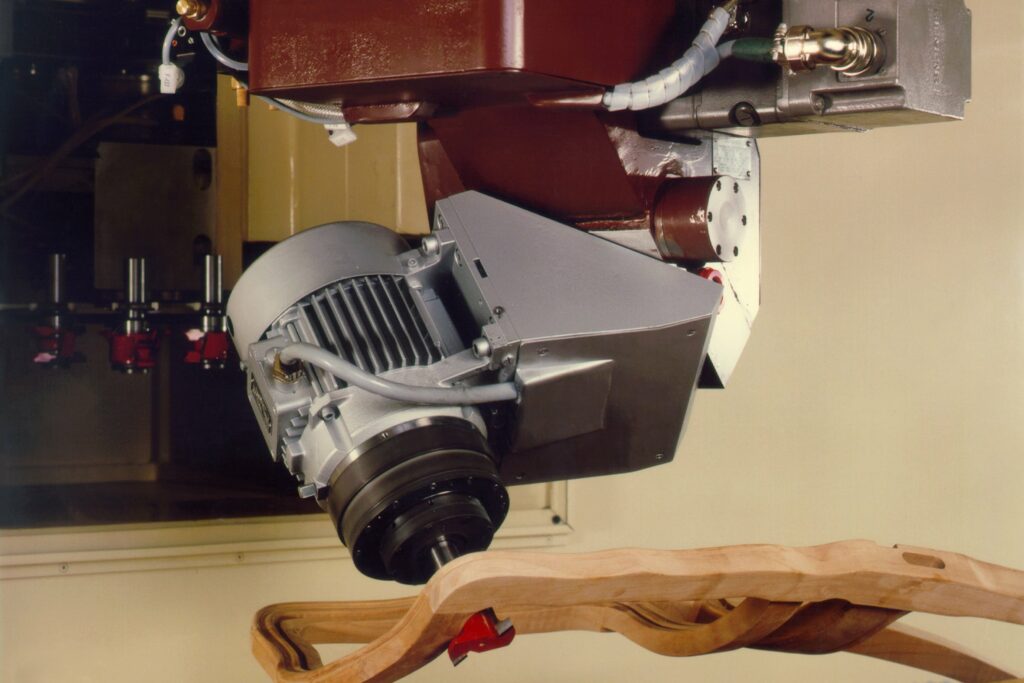

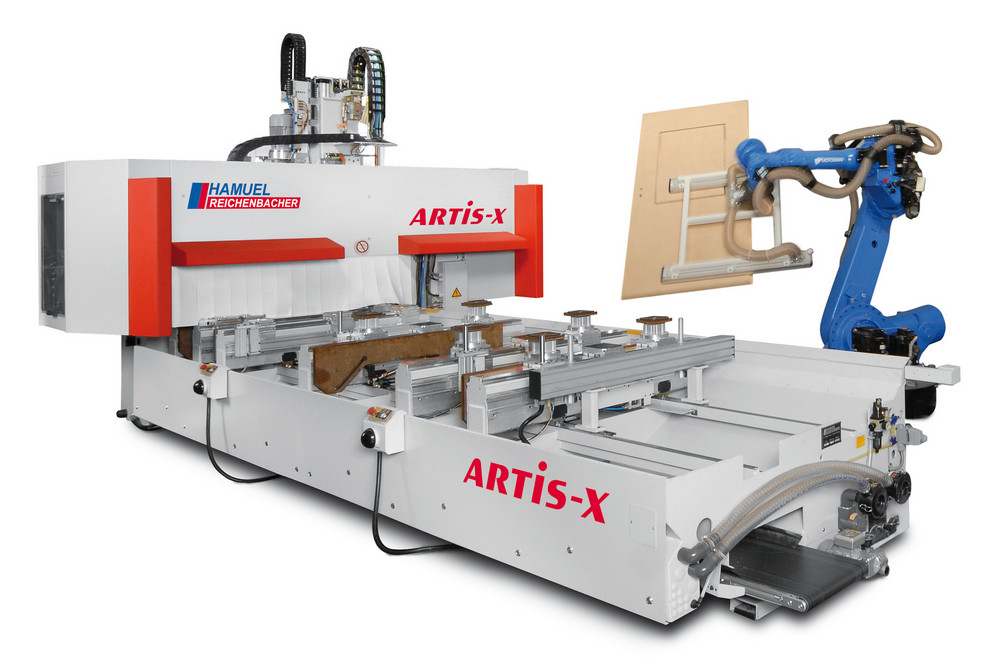

History

Keeping an eye on the wishes of our customers

The success of seven decades of company history proves us right: We always put the customer's wishes at the center of our work. This has made us one of the leading companies in special machine construction to this day.